When evaluating existing structures, forensic test methods are often used to aid in the investigative process. Information regarding the material properties, conditions, and subsurface conditions is paramount in a forensic evaluation to have a clear understanding of the existing conditions. Destructive testing is typically the preferred method to determine existing conditions as it allows for “hands-on” access to the subsurface environment. Where possible, masonry and concrete samples are collected during destructive exploration for laboratory testing. The materials can be tested in a controlled environment to determine their performance characteristics. Often; for a variety of reasons, such as safety, cost, or access; forensic non-destructive test methods are used to evaluate existing structures. This is often the case in masonry and concrete evaluations where destructive methods may not be feasible due to their disruptive nature to the facade or building occupants.

The following are examples of non-destructive test methods that can be used to gather information on the in-situ properties of concrete and masonry structures during a forensic evaluation:

Sounding: used to determine surface delaminations in concrete and certain types of stone. The surface of the concrete or stone is struck lightly with a hammer and the resulting sound is interpreted by the engineer. High pitched sounds typically indicate sound/stable conditions, while lower pitched sounds can indicate delaminations.

- Impact Echo Testing: used to determine flaws in masonry and concrete using a spherical impactor and measuring the stress propagation through the speed of the sound wave. The test can also determine slab thickness accurately.

- Impulse Radar Testing: used to detect delaminations in masonry or concrete structures or debonding between masonry wythes in multi-wythe walls. As the wave travels through each wall material, the different components have different dielectric constant, including air. The energy reflected is measured and the depth to the defect can be determined. This is also used to determine steel reinforcing depth in concrete structures.

Rebound Hammer Testing: used to determine strength of concrete using surface hardness. The hammer is dropped on the surface on which the test is being performed and the rebound is measured; a correlation can be interpreted from rebound to the material’s compressive strength.

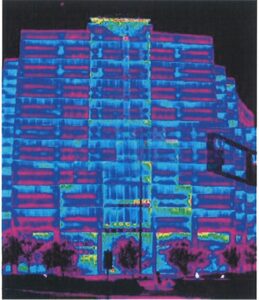

- Infrared Testing: used to determine areas of spalls and voids. A thermographic image is used to show areas with inconsistent materials that affect the thermal properties, resulting in a differing temperature from the surrounding area.

Each of the above tests is used in conjunction with visual observations, and performed and interpreted by a qualified professional. No one test can be considered the sole indicator of material condition. Multiple test methods in several locations are required to substantiate results. As with most exterior building enclosure evaluations, differing building constructions and conditions will necessitate the appropriate approaches and testing.

Tagged In:

Building Enclosure Design & Consulting